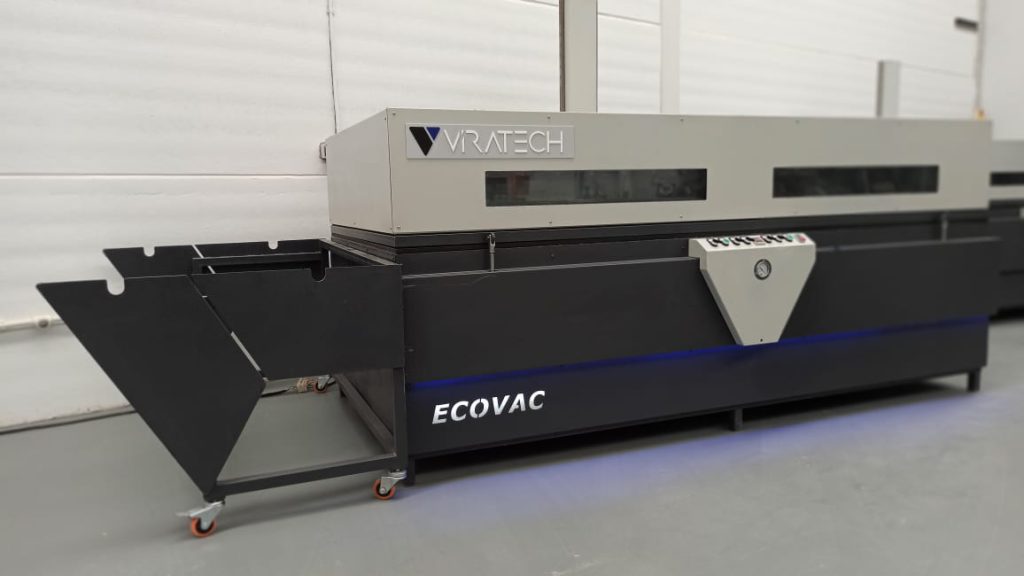

?What is a vacuum press machine

Vacuum pressing machine is a machine that is used for wood veneer. People who are involved in the profession of cabinet making, wood industry, decoration and production of decorative accessories, this device is good.

they recognize. This sophisticated machine has components that create creativity in the production of products made of wood.

You must have seen pvc and mdf coatings on wood, which has various uses in different places. These coatings are installed on the wood by vacuum press machine to increase the quality of work Becomes.

For a complete definition of a vacuum press machine, it should be said: This machine has a great reputation among other industrial machines using unique and special methods. This device has two

The word press and vacuum is formed. The word press means to apply pressure. The second part of this word, vacuum, means vacuum, which can finally be said because of this name

The placement of the extra layer is done by applying pressure and creating a vacuum by this device. This machine in Iran with names such as mdf coating machine, membrane press machine, machine

PVC veneer and so on are known.

Vacuum press machine parts:

Control and design system: This part is one of the most important parts of the vacuum press machine and is known as the design and control part of the machine because in this part it is specified that

Exactly what pattern should be applied to the design on wood by the machine. This selection is made by the device operator.

Tray: In the tray part, which is another vital part of the device, the final form of the part is specified. This part of the vacuum press machine is powered by electrical elements

It is embedded, creating a lot of heat, causing the extra layer to be placed without breaking or cracking.

Suction system: The suction system is located in the tray section and causes vacuum and air suction. When the outer layer is placed on a piece, there should be no air between the two layers

Do not hold the layer well to the piece.

Heating system: As its name suggests, it is responsible for heating the tray by generating heat by electrical elements. This heat eventually causes the layer to stick, with

Provides high quality.

Anti-wrinkle system: This part of the vacuum press machine has a property that prevents wrinkles when the layer sticks.

How does a vacuum press machine work?

As we got in the first part of the article and from its definition, the performance of this device is closely related to heat and vacuum. Therefore, all parts of this device are based on these two components

Is. The control part of this device is done by the operator. The choice of design is also determined by the operator. The operator must have favorable conditions due to factors such as vacuum and heat

Provide a piece for veneering. After going through these steps, we will be able to produce the product.

When the device starts working, its electrical elements turn on and heat the tray part quickly. In the tray section, the main piece is located to be placed on it by an additional layer. After this step

It is the turn of the vacuum cleaner to provide vacuum in the lower parts. If the suction motor and the elements perform well, the final product will be very desirable.

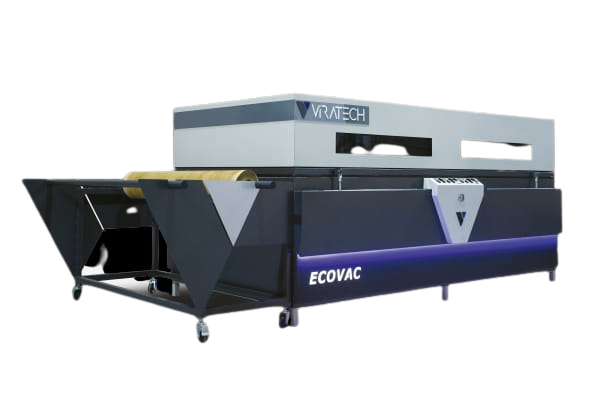

This device has a head that is completely insulated so that the heat generated by the elements is not transferred out of the device. Material of this head according to the type and price of the press

The vacuum is different.

The holes in the bottom of the machine through which the suction action is placed. In different devices, the holes may be embedded in other parts of the device.

Other machines have been produced according to the function of the vacuum press machine, each of which has unique features according to its specific type of application. It is therefore necessary if you intend

You have to buy such a device, according to your needs and the advice of experienced people, buy a suitable vacuum press machine.

For example, in some of these devices in the tray section, there is variety and the number of trays is designed according to the type of application of the device. It is also possible that from rail trays,

Use the elevator and the box.

Elevator vacuum press machine: As its name suggests, its function is in the form of an elevator from top to bottom. The lid and housing of this model are located on the device, which is the task of control

Specifies the pressure and temperature of the device during operation. After starting the device, the lid of the device rises half a meter to vacuum the parts and cover.

Box vacuum press machine: The door of this machine works just like the box door. This machine is also known as Sadafi among its other counterparts and is the most widely used type of press machine

It is considered a vacuum.

Wagon vacuum press machine: One of the most important differences between this type of machine and other similar machines is that it has 2 to 3 trays, and this advantage has made it possible to

When the machine was working, it used other trays and filled them with wood or other products for the pressing stage.

When using this device, time can be easily managed and more products can be produced.

Types of vacuum devices in terms of manual intervention:

The vacuum press machine is fully automatic and semi-automatic, and to the extent that the use of the hand is minimized, it will undoubtedly reduce the human error rate and quality.

Will be the top of the products. It should not be forgotten that a quality product is not cheap and you have to pay the price.

Price of vacuum press machine:

Vacuum press machine is marketed with various brands. Several models of this device are domestically produced, which are suitable and high-quality products and attract many fans

Have attracted. One of the best brands of this device is German. Factors that determine the final price of this device should be: number of trays, automatic and semi-automatic device, number of trays and capacity of trays.